Various assortments accurately as ordered

The cut-to-length (CTL) harvesting method serves to directly produce high-quality timber cut to the required length based on demand. It is based on users’ actual needs – only the trees required are harvested.

Assortment refers to the different types of products cut from a single felled stem, including

sawn wood, plywood and small logs, pulpwood, and wood used to generate bioenergy. In CTL harvesting, we are talking about a machine chain, consisting of a harvester and forwarder.

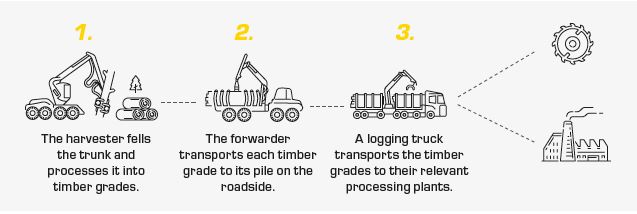

The harvester fells, delimbs, measures, optimises and cuts stems directly into the assortments ordered by the user, normally a forest company. In the CTL method, trees are processed in the forest into different assortments, based on the requested purpose of use. All the assortments required are produced from each stem by processing it once – in the same place in which it was felled. The forest company sends its raw material needs, i.e. places its order, directly to the harvester, detailing the assortment, length and quality requirements. The harvester receives cutting instructions from the forest company and helps the operator produce the assortments ordered. In addition, the harvester optimises each stem based on the order and cuts them to the specified lengths. As a result, the valuable raw material can be used as fully as possible, without generating any waste. The volume of the assortments produced can be monitored automatically in real time.

The forwarder carries the assortments to the side of the forest road, placing each assortment into a separate pile. A timber truck will then transport the assortments to the mill for further processing. Each assortment is transported directly to its correct destination: logs to sawmills; plywood logs to the plywood mill; and pulpwood to the paper or pulp mill. They will then continue their journey to fulfil various purposes in buildings, furniture and various bioproducts.

The aim of harvesting is to minimise machine trails. Eight-wheeled PONSSE forest machines have a balanced weight distribution, and correctly selected tracks can have a significant impact on machine trails. Forwarders have the greatest impact on trails because they drive over the same path multiple times. As it moves and works in the forest, the PONSSE harvester spreads delimbed branches and treetops over trails. This decreases surface pressure and reduces soil damage. In addition, the nutrient-rich leaves, needles, limbs and tops remain in the forest for the next tree generation. A large load space also helps reduce soil damage, as fewer runs are required.

Tended forests grow more quickly and produce higher-quality wood

Forests sequester carbon dioxide from the atmosphere and slow the progress of the greenhouse effect. This is why forests are carbon sinks. Forests are kept healthy through well-executed thinning, which increases the amount of carbon dioxide they sequester. Furthermore, correctly timed thinning reduces the risk of snow and storm damage, wildfires and insect damage. Managed forests grow more quickly and produce higher-quality wood. A fully-grown forest keeps the carbon dioxide it has sequestered, but cannot sequester more

carbon dioxide as effectively as a young, growing forest. Systematic and long-term forest management produces the best results.

The more sustainable products are made from wood, the more slowly the carbon dioxide sequestered in trees is released. Durable wood products such as timber buildings and wooden furniture can be regarded as small carbon stocks. When a larger part of felled trees is used in these products with a slow carbon cycle, the amount of carbon dioxide in the atmosphere decreases. In the CTL method, the largest possible part of felled trees can be processed into valuable and durable logs and subsequently into products with a slow carbon cycle.

CTL forest machines can be used in all harvesting methods, from first thinning to continuous cover forestry and regeneration felling. The fast and reliable regeneration is addressed in all harvesting methods. After all, only the healthy growth of the next tree generation enables the continuation of the forest cycle and the regeneration of the raw material. To enable different harvesting methods, machines must be balanced and strong so that they can use their long crate reach on thinning sites, for example. PONSSE forest machines operate effectively in all conditions – regardless of the weather, time of year or ground surface. The advanced computing capacity of forest machines allows the best possible value to be extracted from forests. This means more than financial gain. By optimising the yield and processing value of the raw material, the maximum amount of sawn timber with a long-term carbon sequestration capacity can be produced.

Cut-to-lenght VS tree-length method

Where the CTL method is not yet used in mechanised harvesting, the tree-length method is usually used. Compared to the tree-length method, CTL is a more effective and environmentally friendly method as a result of such factors as fuel economy and the processing times and work stages required. In addition, less cutting damage and timber contamination, combined with fewer top breaks, mean that the timber quality is higher.

In the CTL method, the machine chain usually consists of a harvester and a forwarder, whereas the tree-length method requires up to four machines. In the tree-length method, all stems are delivered as whole stems to the roadside storage, from where they are usually transported first to a sawmill or interim storage. There, the stems are unloaded and cut for sawing. In other words, stems are not processed into assortments until they have been delivered to the sawmill or interim storage. After this, the stems are loaded once again for transport to various production facilities. The same stems go through several processing cycles, each resulting in more costs and adverse environmental impacts. In the CTL method, stems are already processed into assortments in forests based on their intended use, and logs are transported directly from forests to their correct destinations, without any interim storage or back-and-forth driving. While CTL is the most common harvesting method in the Nordic countries, the tree-length method is still used widely in other parts of the world, including Canada, the United States and Italy.

Global CTL recignition to Chile

The Einari Vidgrén Foundation awarded the Huequecura company from Chile the first-ever Global CTL recognition. With the recognition, the Einari Vidgrén Foundation seeks to encourage and promote sustainable silviculture and the diverse uses of valuable wood raw materials using the cut-to-length (CTL) method.

“The company has been engaged in systematic high-quality harvesting in Chile. It’s important to see how the Nordic CTL method is spreading across the world,” says Juha Vidgrén, Chair of the foundation.

Radiata pine accounts for some 60 per cent and various eucalyptus species for 22 per cent of all planted forests in Chile. Around 40–45 million cubic metres of wood are harvested per year. In Chile, the tree-length method is more common, whereas only about 15 per cent of forest contractors use the CTL method. CTL forest machines were introduced to the Chilean markets in the 1990s.

Established in 2002, Constructora Huequecura Ltda. provides services in forests and civilian areas. The company’s founders have more than 40 years of experience in the forest industry.