Metal waste recycled effectively at the Vieremä factory

“The comprehensive recycling of metal waste is an integral part of high-quality activities at the Vieremä factory,” says production manager Esa Penttinen.

At the Vieremä factory, metal waste generated in production is recycled effectively. According to production manager Esa Penttinen, Ponsse aims to be especially responsible by doing things right and leading the way in environmental matters.

“The recycling of metal waste is an integral part of the system to ensure that all recycled material generated at the plant finds the correct route towards reuse. Metal recycling is also financially profitable,” Penttinen says.

When producing the world’s best forest machines in Vieremä, some excess metal is generated in each phase.

“Parts manufacturing accounts for the most significant part. For example, chipping generates metal waste that must be processed before recycling. Scrap metal is also recycled, including pieces of metal sheets and unsaleable items that can no longer be fixed or reused,” Penttinen says.

“In addition, waste includes pieces of welding electrodes, nozzles, steel, drill bits and threaded rods. Of course, they only account for a small part of the total metal waste volume.”

Metal covers 25–30 per cent of the factory’s total annual waste volume, ranging from several hundreds of thousands of kilograms all the way to half a million kilograms. The goal is to reduce the volume of metal waste in operations.

“Through optimised planning and production, we seek to continuously reduce our waste volume. Eliminating waste is one of Ponsse’s major goals, and achieving it calls for the involvement of all functions, starting with research and development.”

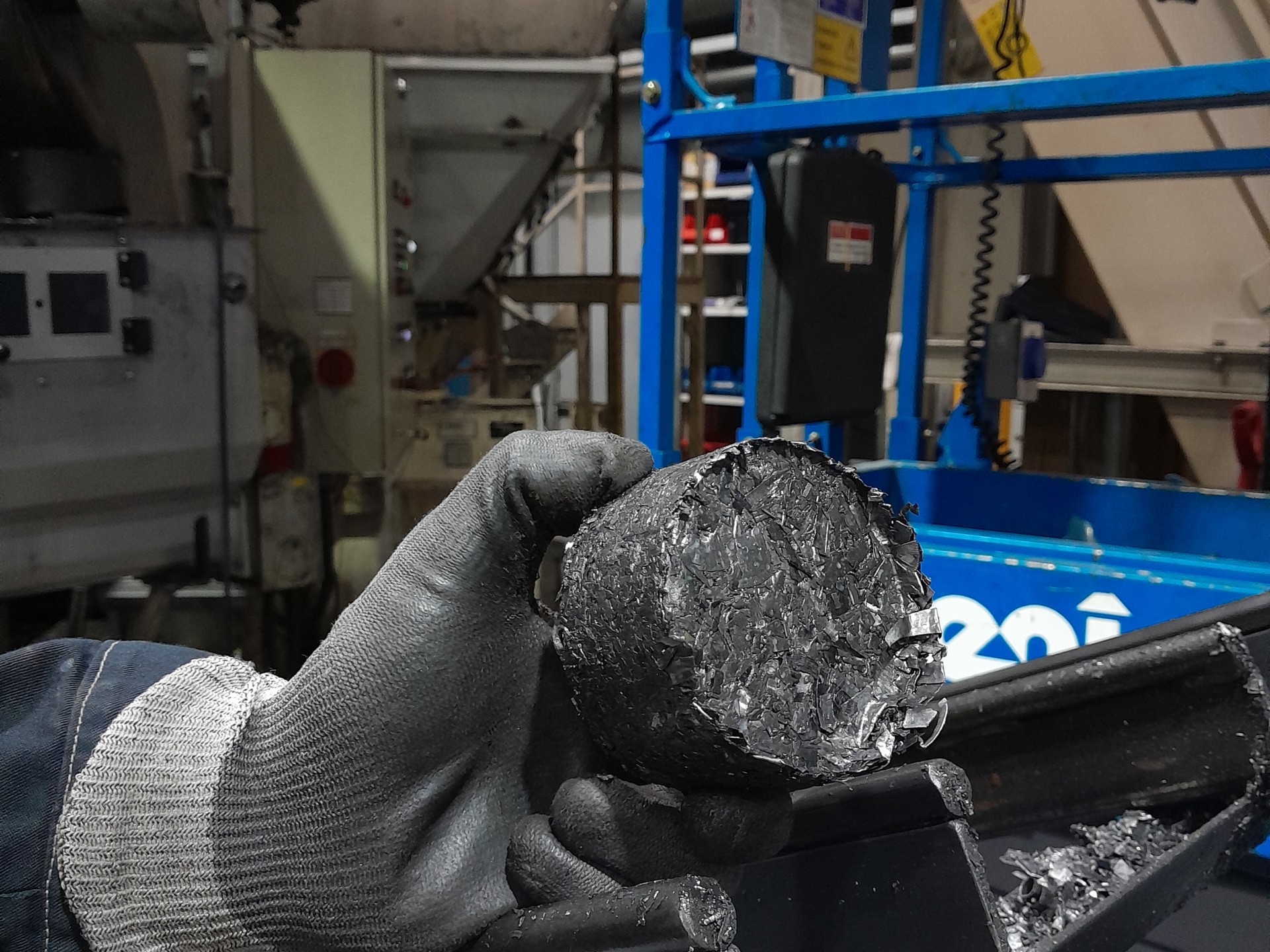

Chipping waste generated by machine tools at the Vieremä factory end up in an automated collection system underneath the floor. The waste is forwarded to a briquetting machine, which separates cutting fluids before compressing the waste into briquettes. The process produces high-quality recycled raw materials for further processing. Waste from machines not connected to the chip collection system end up in the same place.

Esa Penttinen, who has worked for 26 years at Ponsse, says that metal waste was already recycled during the early years of his career.

“We have also carefully sorted copper, brass, aluminium and steel for several years now. The goal is to reduce the volume of mixed waste in operations and recycle everything we can.”

“The professionals working at the Vieremä factory understand the importance of metal recycling and waste sorting and are fully committed to achieving our goal,” Penttinen says.

“Recycling and sorting work like a charm. There is practically no metal in mixed waste, and no other types of metal in steel.”